P&IDs: Decoding the Secrets of Efficient Industrial Automation

The industrial automation world thrives on clear communication and precise planning. One crucial tool that facilitates this is the Piping and Instrumentation Diagram (P&ID). Often referred to simply as a P&ID, it's a visual representation of a process within an industrial facility. Think of it as a roadmap, guiding the design, construction, operation, and maintenance of the system.

What Does a P&ID Show?

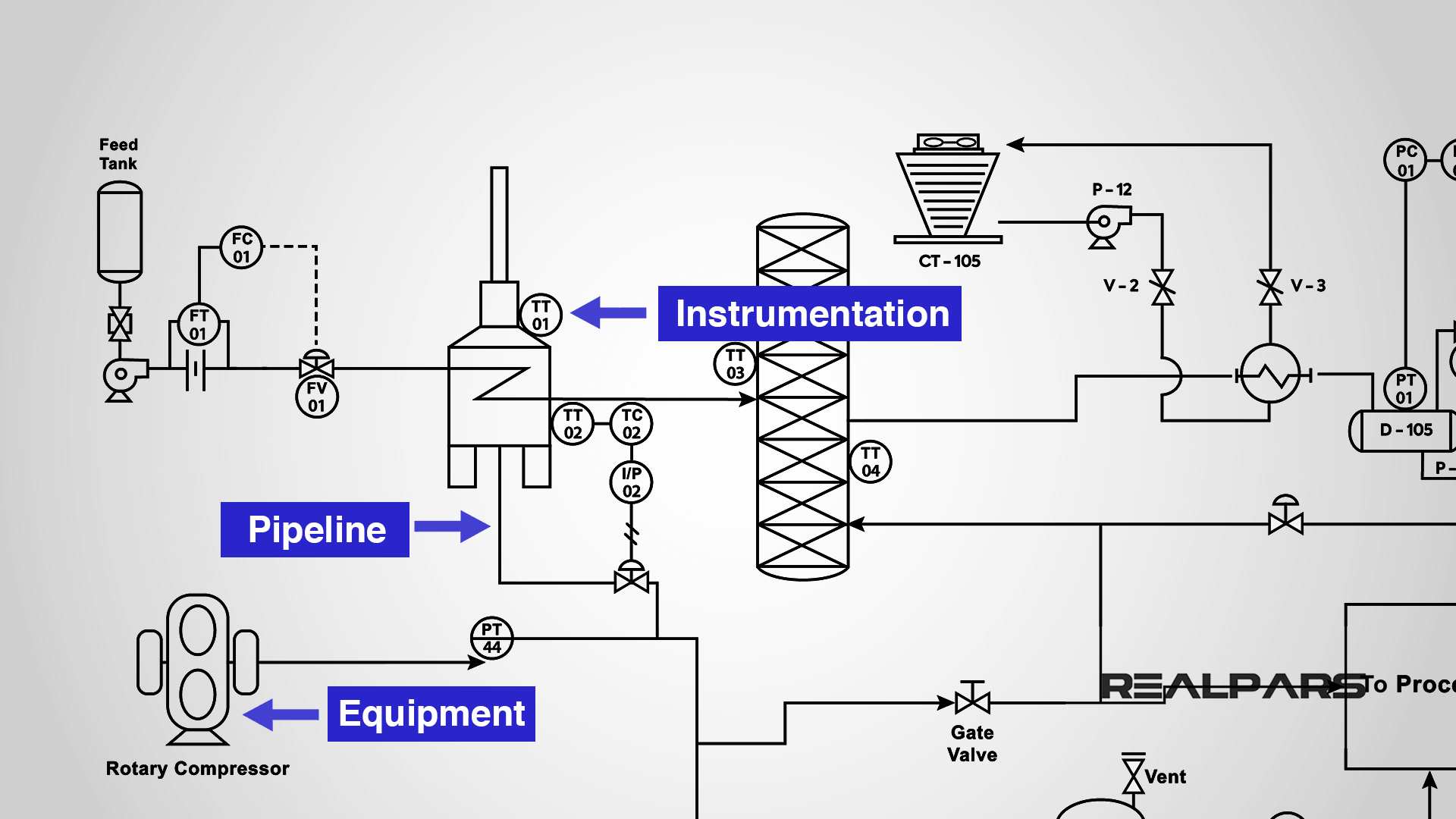

A P&ID is a symbolic representation, not a literal drawing. It focuses on the functionality of the equipment and how they connect, rather than their physical layout. Here are the key components you'll find on a P&ID:

- Process Equipment: Tanks, vessels, reactors, heat exchangers, and other equipment involved in the process are depicted using standardized symbols.

- Piping: Lines represent the flow of materials (liquids, gases, etc.) These lines are often color-coded to differentiate different materials.

- Instrumentation: Instruments like pressure gauges, temperature sensors, and flow meters are represented by symbols, indicating where they are placed in the process for monitoring and control.

- Valves: These control the flow of materials and are depicted by symbols indicating their function (e.g., on/off, pressure relief)

- Control Lines: These dashed lines show the connection between instruments and control systems, allowing for automation.

Benefits of Using P&IDs:

P&IDs offer a multitude of advantages for industrial automation projects:

- Enhanced Communication: A clear visual language ensures everyone involved, from engineers to operators, understands the process flow.

- Improved Design and Planning: P&IDs help identify potential issues and optimize the layout before construction begins.

- Efficient Troubleshooting: By showing the connections and instrumentation, P&IDs make it easier to diagnose problems during operation.

- Effective Maintenance: P&IDs highlight key components requiring maintenance and their location.

- Streamlined Documentation: P&IDs serve as a permanent record of the process flow, facilitating future modifications and upgrades.

Who Uses P&ID?

P&IDs are utilized by various personnel throughout the lifecycle of an industrial automation project:

- Process Engineers: They design the process and create the initial P&ID.

- Control Engineers: They use the P&ID to develop the automation logic and control system.

- Piping Engineers: They translate the P&ID into detailed piping layouts for construction.

- Plant Operators: They rely on the P&ID to understand the process and operate the system safely and efficiently.

- Maintenance Technicians: They use the P&ID to locate equipment and perform maintenance tasks.

The Future of P&ID:

The world of industrial automation is constantly evolving. P&IDs are adapting as well, with the emergence of digital versions. These digital P&IDs (eP&IDs) offer interactive features, allowing users to access real-time data and manipulate the diagram for better visualization. As technology advances, eP&IDs are poised to play an even greater role in streamlining industrial automation processes.

Conclusion:

P&IDs play a vital role in the smooth operation of industrial automation systems. By providing a clear and concise representation of the process flow, P&IDs facilitate communication, planning, and problem-solving across various teams. As the cornerstone of industrial automation documentation, P&IDs will continue to be a valuable tool for years to come.